To start the automation journey, you must

- Organize: define your procedures and processes

- Knowledge transfer: in order to share individual and organizational knowledge you have to write down in procedures and define repeatable best practices and show others how to use it.

- Delivery time: to get your products or solutions to market in a short amount of time implementing automation during product development and production is a realistic way to maximize resources and output.

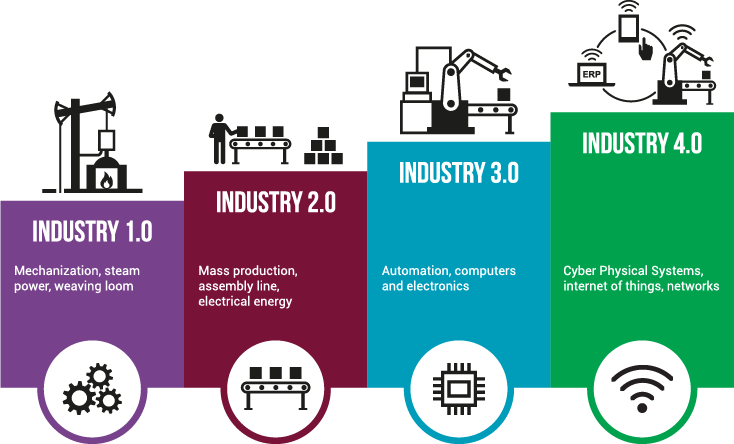

Industry 4.0 represents a significant shift in the way industrial production. It aims to make it more focused on single parts, faster, and more flexible by leveraging the latest technological advancements.

Industry 4.0 is more than just a buzzword; it represents a new manufacturing era that will change how we approach production by empowering us to make decisions based on real-time data and allowing us to be more agile and responsive to changing market conditions. With Industry 4.0, businesses can achieve increased efficiency, improved quality control, and reduced waste, all while increasing their overall competitiveness.

To stay ahead of the game, companies need to embrace Industry 4.0 and all it offers. By taking advantage of this new era of production, businesses can create more value for their customers, stay ahead of their competitors and maintain their position at the forefront of the industry.

Also known as the “Digital Revolution,” is characterized by automating processes using logic processors and information technology. In this era, the automation process is based on human input and decision-making. The introduction of computers and computer-aided design (CAD) tools in this era allowed for significant efficiency, accuracy, and speed improvements.

Also known as the “Fourth Industrial Revolution,” represents a significant shift in production processes. It integrates advanced technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, into production. In Industry 4.0, the same CNC machine could follow set programming parameters and use data to streamline production processes without human intervention. This leads to a more data-driven, automated, and efficient production process, from enterprise resource planning (ERP) to the end piece.

In conclusion, Industry 4.0 represents a step forward from Industry 3.0 by leveraging advanced technologies to automate processes and make production more efficient, accurate, and data-driven.

Also known as the “Fifth Industrial Revolution,” will be characterized by the integration of highly advanced systems, intelligent devices, and intelligent automation (Cobots) with the physical world. This integration will be carried out cooperatively with human intelligence and experiences, leading to a new production efficiency and effectiveness level. In Industry 5.0, production will occur over a cluster of suppliers, making the entire supply chain more connected, agile, and efficient. Integrating these elements will result in a more human-centered, data-driven, and sustainable production process, making Industry 5.0 a crucial step forward in developing modern industrial systems.